Looking for a plug and play alternative for your stock or built late model factory EFI engine? How about a replacement ECU for your older Holley C950? Holley has you covered. HP EFI ECU and harness kits are designed to be used with popular factory EFI engines as an alternative to the factory ECU and harness or as a replacement for your C950 ECU. The HP allows you to accurately control the fuel and ignition of your engine along with additional controls for nitrous, boost or water meth.

HP EFI ECU

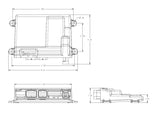

Part #: 554-113- Length: 10"

- Width: 8"

- Height: 25"

- Emissions Code: 3

- Prop 65: No

When utilizing a Transbrake, it is highly recommended to install our Transbrake input protection device. P/N 554-128. This will protect the ECU from any flyback voltage when the transbrake is released.

Holley HP EFI systems are equipped with 4 programmable inputs and 4 programmable outputs that are ideal for most vehicles with a single power adder. This feature allows the user to configure the system to support a wide range of controls including boost control, progressive nitrous, water/meth injection, speed inputs, fuel pump control, AC inputs, timing retard inputs and various other uses. When selecting an ECU, users need to ensure their planned controls can be run with the 4 inputs and 4 outputs as certain combinations may use more I/Os than are available. If more I/Os are required, users should choose the Dominator VMS.

Certified to ISO 8846, SAE J1171 & United States Coast Guard Requirements for Ignition Protection & Fire Resistance.

Software and firmware updates can be downloaded here for free.

FEATURES

NEW V4 SOFTWARE FEATURES - “Quick Start” ignition and fueling strategy for LS x Engines

- Data Logger. Scalable axes

- Smoothing

- Multiple graph view ability

- Pre-defined notes fields and many more

- Strip Chart Real-Time Data Viewer

- Integrated Boost Control - Boost vs Time

- Boost vs Gear (Time or RPM)

- Boost vs RPM

- Boost vs Speed

- Launch control. Boost launch builder

- Over-boost safeties

- Boost scramble

- Traction Control - Power reduction via timing

- nitrous percentage or boost (Requires Davis Technologies Holley Module)

- “Quick Start” fueling for all engines

- Option for VE based fueling strategy

- Fuel Map and Learn Function Smoothing

- Configurable User Password Protection

- Fully Configurable lap top Gauge Panel

FEATURES - Optional 5.7” full-color touchscreen LCD allows easy on-the-fly tuning

- data-logging or can be used as an easy to see graphical gauge panel

- Eight sequentially driven 8:2 peak and hold injector drivers

- capable of driving up to 16 low or high impedance injectors as a standard feature. Multiple staged injector strategies

- Eight channel Distributorless Ignition (DIS)outputs capable of directly driving “Smart” ignition coils or Holley DIS coils. Will drive 2 wire coils with the addition of PN 554-112 high current coil driver module

- Plug and Play control of factory GM 24x and 58x LSx engines

- Integrated single channel wide band oxygen sensor control. Works with NTK or Bosch sensors

- Internal data-logging standard with a huge 2GB of memory

- 4 Stage progressive nitrous control

- Turbo boost control

- Integrated water/methanol injection control

- Self-tuning fuel table strategy greatly simplifies tuning process

- Individual cylinder fuel and spark control allows you to unlock your engine’s potential

- Works with 4

- 6

- 8 cylinder engines

- Unique lb/hr based fueling strategy greatly simplifies and commonizes tuning

- Advanced idle

- closed loop

- and enrichment strategies allow for very stable operation

- ECU is fully potted and can be mounted in the engine compartment or interior

- Sealed automotive and marine grade connectors

- Allows for use of common OEM sensors as well as customer sensor calibration input

- Ignition Plug and Play with GM 24x and 58x LSx engines

- GM HEI

- Ford TFI

- magnetic and hall effect trigger

- and other ignition systems. New Plug and Play applications in process. Custom settings can be configured to allow many other applications

- 1-5 Bar MAP sensor capability

- Two channel knock control sensor Inputs for both one or two wire knock sensors

- Dedicated fuel and oil pressure inputs

- Controls both stepper and PWM Idle Air Control (IAC) motors

- Speed density

- Alpha-N

- or combination fueling strategies

- 4 Programmable high or low Pulse Width Modulated (PWM) outputs and 4 fully configurable inputs can be configured for use

- 4 Stage nitrous oxide control

- Fully featured nitrous control eliminates the need for a separate nitrous controller device

- Can be configured “Wet” or “Dry” with closed loop feedback

- Progressive control based on time

- RPM

- or boost

- requires part # 554-111

- Lean or rich safety cutoff